By Yoshihiro Sugita, General Manager, Industrial Service at TÜV Rheinland Japan

Industrial accidents in Japan

Industrial accidents in Japan

According to recent statistics by the Ministry of Health, Labour and Welfare, the number of industrial accident fatalities is decreasing constantly, except for the extraordinary rise in 2011 because of the Great Kanto Earthquake and the following nuclear power plant accident.

The number reported in 2013 was 1,030, as compared with 2,414 in 1995. Industry-wide, construction, manufacturing and transportation are the three major areas with high numbers of industrial accidents.

Safety inspections – their history started with growing numbers of industrial accidents

Workplace safety inspections play an important role in the avoidance of accidents. Third-party inspections in Europe and the United States were actually begun through attempts to come to grips with increased industrial accidents.

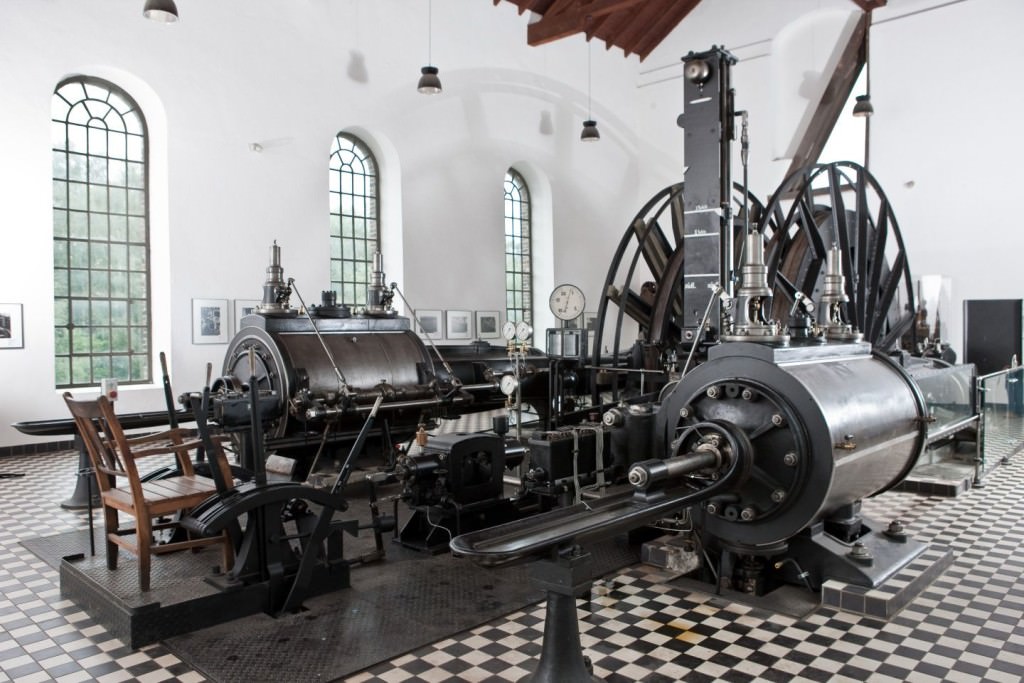

In Europe, third-party inspection started during the Industrial Revolution in the late 19th century. During this period, there was a rapid increase in industrial accidents caused by the operation of pressure vessels. In Germany, the government established a system to accredit qualified inspection companies to perform safety inspections of pressure vessels. TÜV Rheinland started as one such inspection company.

And in Japan – Example chemical plants

What is the present situation in Japan? To get a specific view, let’s take the example of chemical plant safety.

In Japan, the laws that apply to chemical plants, such as petrochemical complexes, include the Fire Service Act, the Industrial Safety and Health Act, and the High Pressure Gas Safety Law. These laws fall under the jurisdictions of these three ministries: The Ministry of Internal Affairs and Communications, the Ministry of Health, Labour and Welfare, and the Ministry of Economy, Trade and Industry.

Accidents at chemical plants

Currently, the number of accidents for the year 2013 can be seen on one of the websites operated by the Japanese government. The accidents covered there include those at hazardous substance handing facilities (including petrochemical complexes) and high-pressure gas production plants in Japan. According to these statistics, the main cause of industrial accidents is chemical leaks (54%), followed by fires (27%).

The number of accidents posted represents those at high-pressure gas production plants, broken out by the type of plant, which is further sub-divided by the type of safety regulations that apply to each type. However, the type of accident is only shown for plants to which the Safety Regulations Concerning Petrochemical Complexes, etc. apply. Only accidents caused by leaks are listed, and the report states that 10 percent of those accidents resulted in an explosion or fire. The classifications of all accidents and the reporting format are not currently standardized, but it is hoped that these items will be appropriately coordinated in the future.

Measures taken by the Japanese government

In 2014, the Ministry of Internal Affairs and Communications (through its Fire and Disaster Management Agency), the Ministry of Health, Labour and Welfare, and the Ministry of Economy, Trade and Industry established a Three-Ministry Liaison Conference on the Prevention of Disasters at Petrochemical Complexes, etc.

The purpose of the Conference is to promote the development and implementation of measures to prevent disasters at chemical plants, including petrochemical complexes. In addition, the three ministries decided they would jointly operate a Conference website to publish information about accidents involving facilities that handle hazardous substances, including petrochemical complexes and high-pressure gas production plants.

As stated earlier, in Japan the safety of chemical plants is overseen by three ministries. The fact that these ministries have established a liaison conference, will share information with each other, and are ready to make relevant information available to the public is a big step forward in the promotion of safety at such plants.

An Official Action Plan to prevent accidents due to hazardous substances

These circumstances set the stage for the Fire and Disaster Management Agency to develop and release its 2014 Action Plan for the Prevention of Hazardous Substance Accidents. The Plan emphasizes the following points: (1) The implementation of safety training to develop the industry’s human resources and to convey safety techniques to younger generations; (2) Risk-specific approaches; (3) The establishment of company-wide safety systems; (4) The promotion of active measures to protect against earthquakes and tidal waves.

It is generally reported that the main causes of fires are improper maintenance and servicing, and that the usual cause of accidents due to leaks is deterioration caused by corrosion or fatigue. This type of deterioration is of course inevitable. It is thus essential to educate personnel so they become capable of performing adequate maintenance and servicing of the facilities, in order to prevent these leaks and thus the accidents they can cause.

Furthermore, it is also necessary for companies to establish company-wide systems that take into account the risks involved in handling hazardous substances, include appropriately timed and constructed reviews of the criteria for periodic inspections, and promote corrective actions, when necessary, in keeping with the inspection’s results. It is hoped that each company will establish an accident prevention system consonant with the Action Plan.

Challenges for the new industrial age

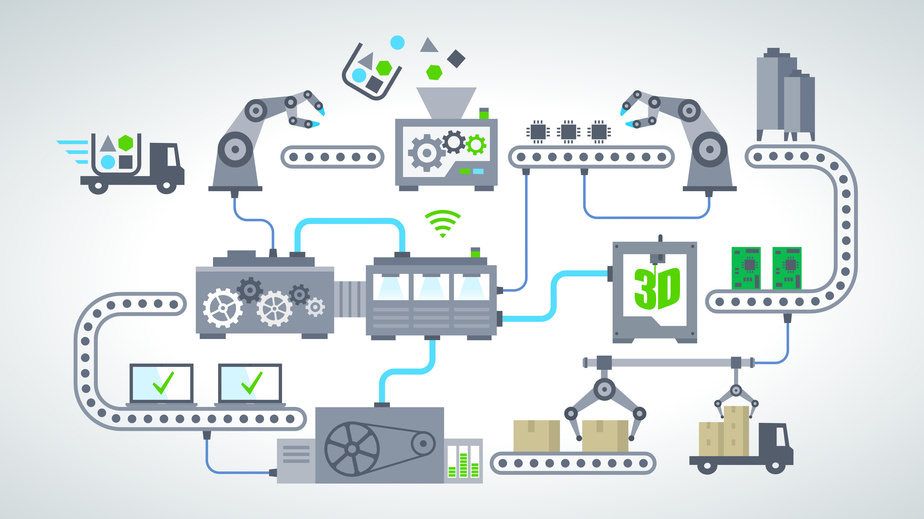

Since the time of the Industrial Revolution, safety has been the mission of third party inspection companies such as TÜV Rheinland. The types of industry have been evolving from those involving physical effort, to machines, and then to electrical devices in the 2nd Industrial Revolution (the Age of Technology) and the 3rd Industrial Revolution (the Information Age). Entering into the 4th Industrial Revolution, the issue of cyber security is becoming critical.

The 4th Industrial Revolution is defined as the “Age of the Cyber Physical System (CPS)” as further advances are made in industrial automation. In other words, the 4th Industrial Revolution results in the realization of the “Smart Factory.” To assure safety in this environment it is necessary to introduce control systems that deal with safety as a factor involving automated functions as well as to establish secure control networks.

In Japan the Cyber Security Law was enacted in November 2014. Its focus is to prevent the penetration of important infrastructure sites such as power plants. The government is responsible for establishing comprehensive regulations while each operator (company) is requested to implement voluntary preventive actions. Conventional factories may be less subject to Cyber Attacks; however, the Cyber Security provisions are essential to the realization of a safe workplace and, in the long run, a safe and secure society.

No comments yet.